Your lab can benefit by updating certain items, but only if you let it.

I’d love to say that every lab I go to is newly built and designed by an expert, but this is almost never the case. I say “almost never” because I have seen great lab design and have also been involved in designing new labs, but it’s not an easy task. Unless you’re starting with a blank slate, working with existing infrastructure can add unexpected design issues.

Most labs were built long before modern instrumentation technologies even existed, while others are repurposed building spaces that may have never been intended to be used as lab space. No matter where your analytical lab falls in these extreme examples, there are a lot of considerations to make the area more enjoyable to work in, and much more efficient!

3 main details many look past, just because they are used to working in the space:

- Unused Instruments

- Outdated Workflow

- Lab Drawers/Storage Space

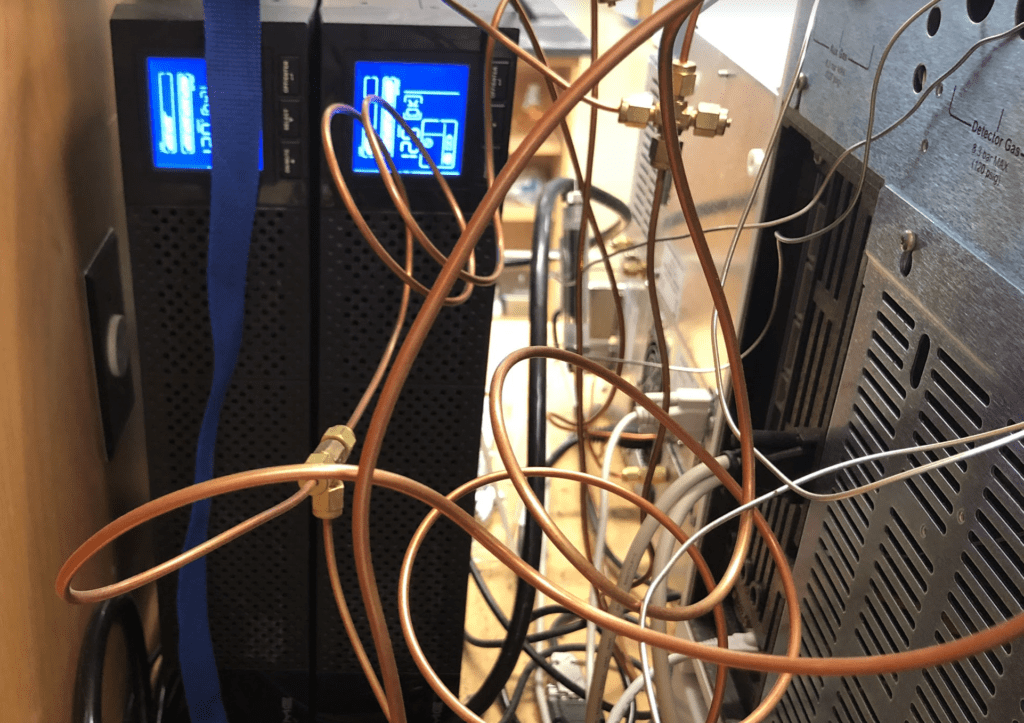

Unused Instrumentation is by far one of the most common things I witness in labs I visit. The system(s) sit on the bench, in a corner, or even under a working instrument! These unused instruments cost the lab thousands in unseen costs per year. Not only are they taking up real estate that is being paid for by the company, but they are also almost always still plugged in, sipping energy the entire time they lay dormant.

Another unintended consequence of these systems sitting around is their role in the workspace’s productivity. Idle instruments can create an untidy and lower-performing lab, intern affecting the lab staff and their work ethic. A clean space automatically breads happy and healthier individuals.

An outdated Workflow can also have a huge impact on productivity. In smaller labs, this is more important as the space is limited and any missed opportunity to optimize the space creates more productivity loss than in a larger more agile lab.

While some cGMP labs may not have the flexibility to move instruments around, other labs can and should if they want to optimize the workspace. Sometimes very small changes, like where the trash receptacles are or how the chemicals are stored (alphabetically), can make an enormous impact. Other times, you have to rethink the entire layout of a single lab. The pain upfront is worth the years of hassle-free workflows!

Lab Drawers/Storage Space is another ubiquitous issue in lab spaces. Everyone knows of the drawers filled with parts to instrumentation that hasn’t even been in the lab for a decade or more. Old broken columns, consumables that will never be used, and tools that are rusted from non-use.

The good news is, that most of these lab space issues are correctable and will end up saving the company in lost time and profits. You just have to be willing to set the time aside to make the changes or hire a professional with the experience to do so.